- Home

- /

- News

- /

- Industry News

What is an AC Motor?

AC Motor Basics

The standard definition for an AC Motor is an electric motor that is driven by alternating current.

The standard definition for an AC Motor is an electric motor that is driven by alternating current.

The AC Motor is used in the conversion of electrical energy into mechanical energy. This mechanical energy is made from utilizing the force that is exerted by the rotating magnetic fields produced by the alternating current that flows through its coils.

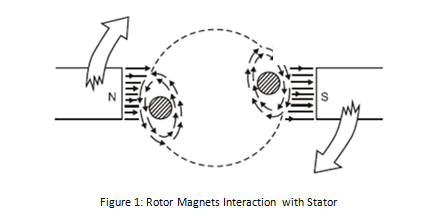

The AC Motor is made up of two major components: the stationary stator that is on the outside and has coils supplied with AC current, and the inside rotor that is attached to the output shaft.

How Does an AC Motor Work?

The fundamental operation of an AC Motor relies on the principles of magnetism. The simple AC Motor contains a coil of wire and two fixed magnets surrounding a shaft. When an electric (AC) charge is applied to the coil of wire, it becomes an electromagnet, generating a magnetic field. Simply described, when the magnets interact, the shaft and the coil of wires begin to rotate, operating the motor.

AC Motor Feedback

AC Motor products have two options for feedback controls. These options are either an AC Motor resolver or an AC Motor encoder. Both the AC Motor resolver and the AC Motor encoder can sense direction, speed, and the position of the output shaft. While both the AC Motor resolver and AC Motor encoder offer the same solution in multiple applications, they are greatly different.

AC Motor resolvers use a second set of stator coils called the transformer to provoke rotor voltages across an air gap. Since the resolver lacks electronic components, it is very rugged and operates over a large temperature range. The AC Motor resolver is also naturally shock resistant, due to how it is designed. The resolver is often used in harsh environments.

The AC Motor optical encoder uses a shutter that rotates to disrupt a beam of light that crosses the air gap between a light source and the photo detector. The rotating of the shutter over time causes wear on the encoder. This wear reduces the durability and dependably of the optical encoder.

The type of application will establish whether a resolver or an encoder is desired. AC Motor encoders are easier to implement and more precise, so they should be the primary preference for any application. A resolver should only be chosen if the environment in which it will be used requires it.

Basic types of an AC Motor

The AC Motor comes in three different types known as Induction, Synchronous, and Industrial. These AC Motor types are determined by the rotor design used in the construction. Anaheim Automation carries all three types in its product line.

Induction AC Motor

Induction AC Motors are referred to as asynchronous motors or rotating transformers. This type of AC Motor uses electromagnetic induction to power the rotating device which is usually the shaft.

The rotor in Induction AC Motor products typically turns slower than the frequency that is supplied to it. Induced current is what causes the magnetic field that envelops the rotor of these motors. This Induction AC Motor is designed in one or three phases.

Synchronous AC Motor

The Synchronous Motor is typically an AC Motor that has its rotor spinning at the same rate as the alternating current that is being supplied to it. The rotor can also turn at a sub multiple of the current it is supplied. Slip rings or a permanent magnet supplied with current is what generates the magnetic field around the rotor.

Industrial AC Motor

AC Industrial Motors are designed for applications requiring a three-phase, high-power induction motor. The power ratings of an industrial motor exceed those of a standard single-phase AC induction motor. Anaheim Automation offers Industrial AC Motors from 220W to 2200W, in 3-Phase operation at 220VAC or 380VAC.

Where are AC Motors used?

What Industries are AC Motors used in?

AC Motors are primarily used in domestic applications due to their relatively low manufacturing costs, and durability, but are also widely used in industrial applications.

What Applications are AC Motors used for?

AC Motors can be found in numerous home appliances and applications, including:

- Clocks

- Power tools

- Disk drives

- Washing Machines and other Home Appliances

- Audio turntables

- Fans

They can also be found in industrial applications:

- Pumps

- Blowers

- Conveyors

- Compressors

How are AC Motors Controlled?

AC Controllers:

Basics

An AC Controller (Sometimes reffered to as a Driver) is known as the device that controls the speed of the AC Motor. An AC Controller can also be referred to as a variable frequency drive, adjustable speed drive, frequency converter, etc.

The AC Motor receives power, which is ultimately converted by the AC Controller into an adjustable frequency. This adjustable output allows the motor speed to be precisely controlled.

Components of an AC Controller

Typically, an AC Controller consists of three basic parts: the rectifier, inverter, and the DC link to connect the two. The rectifier converts AC input into DC (direct current), while the inverter switches the DC voltage to an adjustable frequency AC output voltage. The inverter can also be used to control output current flow if needed. Both the rectifier and inverter are directed by a set of controls to generate a specific amount of AC voltage and frequency to match the AC motor system at a given point in time.

Applications

An AC Controller can be used in many different industrial and commercial applications. Most often used to control fans in air conditioning and heating systems, the AC Controller allows for more control of the airflow. The AC Controller also aids in adjusting the speed of pumps and blowers. More recent applications include conveyors, cranes and hoists, machine tools, extruders, film lines, and textile-fiber spinning machines.

Advantages and Disadvantages

Advantages

- Increases the life of the motor due to high power factor

- Economical speed control

- Optimize motor-starting characteristics

- Lower maintenance than DC control

Disadvantages

- Generates a large amount of heat and harmonics

Variable Frequency Drives

Basics

The Variable Frequency Drive is a particular kind of adjustable-speed drive that is used to control the speed of an AC motor. In order to control the motor's rotational speed, a Variable Frequency Drive controls the frequency of the electrical power supplied to it.

Adding a Variable Frequency Drive to an application allows the motor speed to be adjusted in accordance with the motor's load, ultimately saving energy. Commonly used in a myriad of applications, a Variable Frequency Drive can be found operating ventilation systems, pumps, conveyors and machine tool drives.

How a Variable Frequency Drive Works

When complete voltage is applied to an AC motor, it accelerates the load and drops torque initially, keeping current especially high until the motor reaches full speed. A Variable Frequency Drive operates differently; it eliminates excessive current, increasing voltage and frequency in a controlled manner as the motor starts.

This allows the AC motor to generate up to 150% of its rated torque, which could potentially be generated from the beginning, all the way up to full speed, without wasting energy. A Variable Frequency Drive converts power through three different stages.

First, AC power is converted to DC power, followed by the switching on and off of the power transistors, causing a voltage waveform at the desired frequency. This waveform then adjusts output voltage according to the preferred designated value.

Physical Properties

Typically, a Variable Frequency Drive system involves an AC motor, controller, and operator interface. The three-phase induction motor is most commonly applied to a Variable Frequency Drive because it offers versatility and cost-effectiveness in comparison to a single-phase or synchronous motor. Though they can be advantageous in some circumstances, a Variable Frequency Drive system often utilizes motors that are designed for fixed-speed operation.

Variable Frequency Drive operator interfaces allow for the user to adjust operating speed, and start and stop the motor. The operator interface might also allow the user to switch and reverse between automatic control, or manual speed adjustment.

Advantages of a Variable Frequency Drive

- Process temperature can be controlled without a separate controller

- Low maintenance

- Longer lifespan for the AC motor and other machinery

- Lower operating costs

- Equipment in the system that cannot handle excessive torque is protected

Types of Variable Frequency Drives

There are three common Variable Frequency Drives (VFDs) that offer both advantages and disadvantages depending on the application they are used for. The three common VFD designs used include: Current Source Inverter (CSI), Voltage Source Inverter (VSI), and Pulse Width Modulation (PWM).

However, there is a fourth type of VFD called Flux Vector Drive, which is emerging in popularity among end-users for its closed-loop control feature. Each VFD consists of a Converter, DC Link and Inverter section but how each one is constructed varies from drive to drive. Although the sections of each VFD are similar, they require a variation in circuitry in how they supply the frequency and voltage to the motor.

Current Source Inverter (CSI)

A Current Source Inverter (CSI) is a type of variable frequency drive (VFD) which converts incoming AC voltage and varies the frequency and voltage supplied to the AC Induction Motor. The general configuration of this type of VFD is like that of other VFDs in that it consists of a Converter, DC Link, and Inverter.

The converter part of the CSI uses silicon-controlled rectifiers (SCRs), gate-commutated thyristors (GCTs) or symmetrical gate-commutated thyristors (SGCTs) to convert the incoming AC voltage to a variable DC voltage. In order to maintain the correct voltage to frequency (Volt/Hertz), the voltage must be regulated by the correct sequencing of the SCRs.

The DC Link for this type of variable frequency drive uses an inductor to regulate the current ripple and to store the energy used by the motor. The inverter, which is responsible for converting the DC Voltage back to an AC sine-like waveform, comprises of SCRS, gate turn-off thyristors (GTOs) or symmetrical gate-commutated thyristors (SGCTs).

These thyristors behave like switches which are turned on and off to create pulse width modulation (PWM) output that regulates the frequency and voltage to the motor. CSI variable frequency drives regulate current, require a large internal inductor and a motor load to operate.

An important note about CSI VFD designs is the requirement of input and output filters which are necessary due to high harmonics in the power input and poor power factor. To work around this issue, many manufacturers implement either input transformers or reactors and harmonic filters at the point of common coupling (users electrical system connected to the drive) to help reduce the effects harmonics have on the drive system.

Of the common VFD drive systems, CSI VFDs are the only type of drives that have regenerative power capability. Regenerative power capability means that power is driven back from the motor to the power supply can be absorbed.

Advantages of CSI

• Regenerative power capability

• Simple circuitry

• Reliability (Current Limiting Operation)

• Clean current waveform

Disadvantages of CSI

• Motor cogging when PWM output is below 6 Hz

• Inductor used are large and costly

• Large power harmonic generation sent back into power source

• Dependent on motor load

• Low input power factor

Voltage Source Inverter (VSI)

The converter section of the VSI is similar to the converter section of the CSI in that the incoming AC Voltage is converted into a DC Voltage. The difference from the CSI and VSI converter section is that the VSI uses a diode bridge rectifier to convert the AC Voltage to DC Voltage.

The DC Link of the VSI uses capacitors to smooth out the ripple in the DC voltage and to also store energy for the drive system. The inverter section is comprised of insulated gate bipolar transistors (IGBTs), insulated gate-commutated thyristors (IGCTs) or injection-enhanced gate transistors (IEGTs).

These transistors or thyristors behave like switches which are turned on and off to create a pulse width modulation (PWM) output that regulates the frequency and voltage to the motor.

Advantages of VSI

• Simple Circuitry

• Can be used with applications requiring multiple motors

• Not dependent on load

Disadvantages of VSI

• Large power harmonic generation into power source

• Motor cogging when PWM output is below 6 Hz

• Non-Regenerative operation

• Low power factor

Pulse Width Modulation (PWM)

The Pulse Width Modulation (PWM) Variable Frequency Drive (VFD) is among the most commonly used controllers and has proven to work well with motors that range in size from 1/2HP to 500HP.

Most PWM VFDs are rated for 230V or 460V, 3-Phase operation, and provide output frequencies in the range of 2-400Hz. Like the VSI VFD, the PWM VFD uses a diode bridge rectifier to convert the incoming AC voltage to a DC voltage. The DC Link uses large capacitors to remove the ripple evident after the rectifier and creates a stable DC bus voltage.

The six-step inverter stage of this driver uses high power rated IGBTs which turn on and off to regulate the frequency and voltage to the motor. These transistors are controlled by a microprocessor or motor IC which monitors various aspects of the drive to provide the correct sequencing.

This produces a sine-like waveform output to the motor. So how does turning a transistor on and off help create the sine-like wave output? By varying the voltage pulse width you are obtaining an average power which is the voltage supplied to the motor. The frequency supplied to the motor is determined by the number of positive to negative transitions per second.

Advantage of PWM

• No motor cogging

• Efficiencies from 92% to 96%

• Excellent input power factor due to fixed DC bus voltage

• Low initial cost

• Can be used with applications requiring multiple motors

Disadvantages of PWM

• Non-Regenerative operation

• High frequency switching may cause motor heating and insulation breakdown

How to Select an AC Motor

In order to select the appropriate AC Motor for a given application, one needs to determine basic specifications. Calculate the required load torque and operating speed. Remember that induction and reversible motors cannot be adjusted; they require a gearhead. If this is needed, select the appropriate gear ratio. Next determine frequency, and power supply voltage for the motor.

Advantages and Disadvantages

Advantages of an AC Motor

- Low Cost

- Long Lifespan

- High-Efficiency and Reliability

- Simple Construction

- High Starting Torque (Induction)

- No Slip (Synchronous)

Disadvantages of an AC Motor

- Frequency Causes Rotation Slips (Induction)

- Starting Switch Needed (Induction)

Troubleshooting an AC Motor

The following steps may be taken to troubleshoot an AC Motor and Controller system:

Step 1: Check the motor's smell. If there is a burning smell, replace the motor immediately.

Step 2: Check the motor's input voltage. Ensure wires are not damaged and the proper power supply is connected.

Step 3: Listen for loud vibration or squeaking noises. Such noises may indicate damaged or worn-out bearings. If possible, lubricate the bearings, otherwise replace the motor completely.

Step 4: Check for overheating. Use compressed air to rid the motor of debris, allow to cool, and restart.

Step 5: AC Motors that make an effort to start but fail, may be a sign of a bad starting capacitor. Check for any signs of leaking oil, and replace the capacitor if this is the case.

Step 6: Ensure the application the motor is rotating is not locked up. Do this by disconnecting the mechanism and try running the motor by itself.

How Much do AC Motor Products Cost?

The AC Motor can be a reasonable cost-effective solution to your application requirements. The construction materials along with how the motor is designed, make AC Motor systems an affordable solution. The AC Motor operates with a rotating magnetic field and does not use brushes.

This enables the cost of the motor to be lower, and eliminates the component that could wear over time. AC Motor products do not require a driver to operate. This saves initial setup costs. Today's manufacturing processes makes producing AC Motor products easier and quicker than ever.

The stator is made out of thin laminations that can be pressed or punched out of a CNC machine. Many other parts can be quickly made and perfected saving both time and money! Anaheim automation offers a full line of AC Motor products to choose from.

Physical Properties of an AC Motor

Typically, the AC Motor consists of two main components: the stator and the rotor. The stator is the stationary part of the motor, consisting of several thin laminations wound with an insulated wire, forming the core.

The rotor is connected to the output shaft on the inside. The most common type of rotor used in an AC Motor is the squirrel cage rotor, named after its resemblance to rodent exercise wheels.

The stator mounts inside the motor's enclosure, with the rotor mounted inside, and a gap separating the two from touching each other. The enclosure is the motor's frame, containing two bearing houses.

AC Motor Glossary

AC Motor – An electric motor that is driven by an alternating current, as opposed to a direct current.

Alternating Current – Electric charge that frequently reverse in direction (Opposite of direct current, with charge in only one direction).

Centrifugal Switch – The electric switch that controls the rotational speed of a shaft, operating off of the centrifugal force generated from the shaft itself.

Gear Ratio – The ratio at which the motor's speed is reduced by the gearhead. The speed at the output shaft is 1 Gear Ratio x the motor speed.

Inverter - The device that converts direct current to alternating current. Reverse of the Rectifier.

Induction Motor – Can be referred to as asynchronous motor; type of AC motor where electromagnetic induction supplies power to the rotor. Slip is required to produce torque.

No Load Speed – Typically lower than synchronous speed, it is the speed when the motor is not carrying a load.

Rated Speed – The speed of the motor at rated output power. Typically the most sought-after speed.

Rectifier – The device that converts alternating current to direct current within a motor. They can be utilized as a component in a power supply, or can detect radio signals. Typically rectifiers may consist of solid state diodes, mercury arc valves, or other substances. Reverse of the inverter.

Rectification – The process by which alternating current is converted to direct current by means of a rectifier within an AC Motor.

Split Phase Induction Motor – Motors that can generate more starting torque by using a centrifugal switch combined with a special startup winding.

Stall Torque – Given a particular voltage and frequency, the maximum torque in which the motor can run. Exceeding this amount will cause the motor to stall.

Starting Torque – The torque that instantly generated as the motor starts. The motor will not run if friction load exceeds torque.

Static Friction Torque – When a motor is stopped by a brake for example, it is the torque output needed to hold a load as the motor stops.

Synchronous Motor – Unlike the induction motor, it can produce torque at synchronous speed, without slip.

Synchronous Speed – Indicated by speed per minute, it is the intrinsic factor determined by number of poles and line frequency.

Variable Speed Drive – Equipment used to control electric power frequency supplied to an AC motor, in order to manage its rotational speed.

Block Diagram for Systems That Use an AC Motor

Lifetime of an AC Motor

Anaheim Automation AC Motors typically have a service life of about 10,000 operating hours, given the motors are operating under proper conditions, and in accordance to the specifications.

Required Maintenance for an AC Motor

Preventative maintenance is the key to a long-lasting AC Motor system. Routine inspection should be implemented. Always check the AC Motor for dirt and corrosion. Dirt and debris can clog air passages and reduce airflow, ultimately reducing insulation life and possible motor failure.

When debris is not blatantly visible, check to ensure air flow is steady and not weak. This could potentially point towards clogging as well. In moist, humid, or wet environments, check for corroded terminals in the conduit box and repair when necessary.

Listen for excessive noise or vibration, and feel for excessive heat. This could indicate lubrication of the bearings is needed. Note: Be cautious when lubricating the bearings as excessive lubrication may lead to dirt and oils clogging air flow. Be sure to locate and remove the source of heat for the motor to avoid system failure.

Note: Be cautious when lubricating the bearings as excessive lubrication may lead to dirt and oils clogging air flow. Be sure to locate and remove the source of heat for the motor to avoid system failure.

AC Motor Wiring

The following information is intended as a general guideline for wiring of the Anaheim Automation AC Motor product line. Be aware that when you route power and signal wiring on a machine or system, radiated noise from the nearby relays, transformers, and other electronic devices can be inducted into the AC Motor and encoder signals, input/output communications, and other sensitive low voltage signals. This can cause system faults.

WARNING - Dangerous voltages capable of causing injury or death, may be present in the AC Motor system. Use extreme caution when handling, wiring, testing, and adjusting during installation, set-up, tuning, and operation.

Don't make extreme adjustments or changes to the AC Motor system parameters, which can cause mechanical vibration and result in failure and/or loss. Once the AC Motor system is wired, do not run by switching On/Off the power supply directly. Frequent power On/Off switching will cause fast aging of the system components, which will reduce the lifetime of AC Motor system.

Strictly comply with the following rules:

• Follow the Wiring Diagram with each AC Motor and/or controller

• Route high-voltage power cables separately from low-voltage power cables

• Segregate input power wiring and AC Motor power cables from control wiring and motor feedback cables. Maintain this separation throughout the wire run.

• Use shielded cable for power wiring and provide a grounded 360 degree clamp termination to the enclosure wall. Allow room on the sub-panel for wire bends.

• Make all cable routes as short as possible.

• Allow for adequate air-flow

• Keep environment as clean as possible

NOTE: Factory made cables are recommended for use in our AC Motor systems. These cables are purchased separately, and are designed to minimize Electro-Magnetic Interference. These cables are recommended over customer-built cables to optimize system performance and to provide additional safety for the AC Motor system, as well as the user.

WARNING - To avoid the possibility of electrical shock, perform all mounting and wiring of the AC Motor prior to applying power. Once power is applied, connection terminals may have voltage present.

AC Motor Mounting

The following information is intended as a general guideline for the installation and mounting of the AC Motor system. WARNING - Dangerous voltages capable of causing injury or death may be present in the AC Motor system. Use extreme caution when handling, testing, and adjusting during installation, set-up, and operation.

It is very important that the wiring of the AC Motor be taken into consideration upon installation and mounting. Subpanels installed inside the enclosure for mounting system components, must be a flat, rigid surface that will be free from shock, vibration, moisture, oil, vapors, or dust.

Remember that the AC Motor will produce heat during work; therefore, heat dissipation should be considered in designing the system layout. Size the enclosure so as not to exceed the maximum ambient temperature rating.

It is recommended that the AC Motor be mounted in position as to provide adequate airflow. The AC Motor should be mounted in a stable fashion, secured tightly.

NOTE: There should be a minimum of 10mm between the AC Motor and any other devices mounted in the system/electric panel or cabinet.

In order to comply with UL and CE requirements, the AC Motor system must be grounded in a grounded conducive enclosure offering protection as defined in standard EN 60529 (IEC 529) to IP55 such that they are not accessible to the operator or unskilled person. As with any moving part in a system, the AC Motor should be kept out of the reach of the operator.

A NEMA 4X enclosure exceeds those requirements providing protection to IP66. To improve the bond between the power rail and the subpanel, construct your subpanel out of zinc-plated (paint-free) steel. Additionally, it is strongly recommended that the AC Motor system be protected against electrical noise interferences. Noise from signal wires can cause mechanical vibration and malfunctions.

Environmental Aspects for an AC Motor

The following environmental and safety considerations must be observed during all phases of operation, service and repair of an AC Motor system. Failure to comply with these precautions violates safety standards of design, manufacture and intended use of the AC Motor.

Please note that even a well-built AC Motor system operated and installed improperly, can be hazardous. Precaution must be observed by the user with respect to the load and operating environment. The customer is ultimately responsible for the proper selection, installation, and operation of an AC Motor and/or speed controller.

The atmosphere in which an AC Motor is used must be conducive to good general practices of electrical/electronic equipment. Do not operate the AC Motor system in the presence of flammable gases, dust, oil, vapor or moisture. For outdoor use, the AC Motor must be protected from the elements by an adequate cover, while still providing adequate air flow and cooling.

Moisture may cause an electrical shock hazard and/or induce system breakdown. Due consideration should be given to the avoidance of liquids and vapors of any kind. Contact the factory should your application require specific IP ratings. It is wise to install the AC Motor in an environment which is free from condensation, electrical noise, vibration and shock.

Additionally, it is preferable to work with the AC Motor system in a non-static protective environment. Exposed circuitry should always be properly guarded and/or enclosed to prevent unauthorized human contact with live circuitry. No work should be performed while power is applied.

Do NOT plug in or unplug when power is ON. Wait for at least 5 minutes before doing inspection work on the AC Motor system after turning power OFF, because even after the power is turned off, there will still be some electrical energy remaining in the capacitors of the internal circuit of the AC Motor system.

Plan the installation of the AC Motor in a system design that is free from debris, such as metal debris from cutting, drilling, tapping, and welding, or any other foreign material that could come in contact with system's circuitry. Failure to prevent debris from entering the AC Motor system can result in damage and/or shock.

Newer articles

- DC Motor Selection for Dynamic Motion Control Applications (04/12/2017)

- The Pros and Cons to Different Gear Motors (05/12/2017)

- Gear Reduction (07/12/2017)

- How does a Gear Reducer Works (07/12/2017)

- Difference between 50Hz and 60Hz frequency (30/11/2017)

- Frequency inverter benefits in your application (30/11/2017)

- Advantages and disadvantages of different types of gears (01/09/2018)

- Single-Phase Motor - Types, Uses, Advantages and Disadvantages (30/11/2017)

- How to properly operate a three-phase motor using single-phase power (30/11/2017)

- What are Brushless DC Motors (31/05/2019)

Older articles

- Gearbox Motors vs Integrated Gearmotors (16/04/2008)

- AC or DC? brushed DC or brushless DC Gear Motor? (24/04/2008)

- Getting the most out of gearboxes (29/11/2017)

- Gear motor Selection: Gearbox Reducer Housing Materials (10/10/2017)

- Business Marketing: Understand What Customers Value (30/11/2017)

- Measuring and Managing Customer Satisfaction (29/11/2017)

- The Power of Personal Brands in Customer Service (29/11/2017)

- Selecting Motors for Industrial Applications (22/11/2017)

- Different types of motors and their use (22/11/2017)

- Determining Gear Ratio and Its Importance (22/11/2017)

Join