- Home

- /

- News

- /

- Industry News

Parallel shaft gear motors, applications and advantages

On every electromechanical engineering project, it is of utmost importance to think about how each actuation is to be performed.

In order to accomplish them, there are different types of gear motors on the market, but the best choice will depend on the movement we want to accomplish, the power, or the space that is available.

In this article we introduce you to an actuation system that may be very useful for certain applications: the parallel shaft gear motors. Do you want to learn about its applications and advantages?

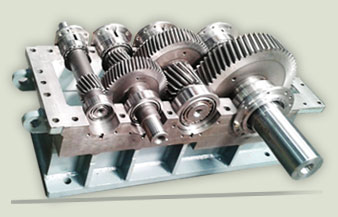

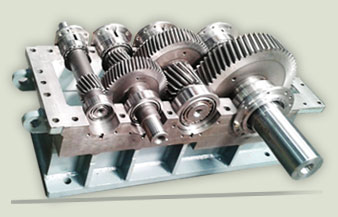

Parallel shaft gear motors are a type of gear motor which uses gears to accomplish the speed reduction. They are called “parallel shaft” since the motor shaft and the speed reducer shaft are on parallel planes. It is precisely this disposition that enables for quite flat gearboxes, which are ideal for applications where space is limited, such as stirrers for liquid mixing processes.

The parallel shaft gear motor may use three types of gears to accomplish the transmission. Choosing one or the other will depend on the final application and the characteristics we need to obtain within the speed reducer:

Spur gears: they are the most widespread. The teeth on their toothed wheels are straight and parallel to the driveshaft of the speed reducer.

Helical gears: their teeth are oblique to the axis of rotation. They transfer greater power and speed. They are likewise more silent and enduring.

Double helical gears: used to eliminate the axial thrust; in other words, the rotation elicited by the shaft itself.

What are the advantages of the parallel shaft gear motors?

Compact design, which translates into less space and weight when compared to coaxial shaft gear motors.

Parallel shaft gear motors may reach a power rating of up to 200 kW and a nominal torque for the speed reducer of up to 20,000 Nm.

They withstand a high torque and great radial forces.

Low vibration, and therefore, low noise levels.

Dolin’s success stories applying parallel shaft gear motors

Case 1: Speed reducer for a peristaltic pump: a leading company of the hygiene and industrial treatment sector needed to improve the operation of the gear motor they had been using at the time.

For this project, a system using parallel shaft gear motors was developed in order to optimise the performance of the peristaltic pumps in charge of distributing and dosing the fluid products without altering them and preventing direct contact of the liquids with the machines, since they could get damaged.

The system was so successful that is has been adapted to other mechanisms with the same effectiveness.

Case 2: Product dispensing in vending machines: a major national vending machine manufacturing company contacted DOLIN in 1946 to find the perfect solution for automatically dispensing cigarette packs on its vending machines.

Dolin developed a custom solution using parallel shaft gear motors, thanks to which they achieved the required power in spite of the reduced space. From that moment on, Dolin has been innovating non-stop to offer solutions across all of its vending-related product range.

In this article we introduce you to an actuation system that may be very useful for certain applications: the parallel shaft gear motors. Do you want to learn about its applications and advantages?

Parallel shaft gear motors are a type of gear motor which uses gears to accomplish the speed reduction. They are called “parallel shaft” since the motor shaft and the speed reducer shaft are on parallel planes. It is precisely this disposition that enables for quite flat gearboxes, which are ideal for applications where space is limited, such as stirrers for liquid mixing processes.

The parallel shaft gear motor may use three types of gears to accomplish the transmission. Choosing one or the other will depend on the final application and the characteristics we need to obtain within the speed reducer:

Spur gears: they are the most widespread. The teeth on their toothed wheels are straight and parallel to the driveshaft of the speed reducer.

Helical gears: their teeth are oblique to the axis of rotation. They transfer greater power and speed. They are likewise more silent and enduring.

Double helical gears: used to eliminate the axial thrust; in other words, the rotation elicited by the shaft itself.

What are the advantages of the parallel shaft gear motors?

Compact design, which translates into less space and weight when compared to coaxial shaft gear motors.

Parallel shaft gear motors may reach a power rating of up to 200 kW and a nominal torque for the speed reducer of up to 20,000 Nm.

They withstand a high torque and great radial forces.

Low vibration, and therefore, low noise levels.

Dolin’s success stories applying parallel shaft gear motors

Case 1: Speed reducer for a peristaltic pump: a leading company of the hygiene and industrial treatment sector needed to improve the operation of the gear motor they had been using at the time.

For this project, a system using parallel shaft gear motors was developed in order to optimise the performance of the peristaltic pumps in charge of distributing and dosing the fluid products without altering them and preventing direct contact of the liquids with the machines, since they could get damaged.

The system was so successful that is has been adapted to other mechanisms with the same effectiveness.

Case 2: Product dispensing in vending machines: a major national vending machine manufacturing company contacted DOLIN in 1946 to find the perfect solution for automatically dispensing cigarette packs on its vending machines.

Dolin developed a custom solution using parallel shaft gear motors, thanks to which they achieved the required power in spite of the reduced space. From that moment on, Dolin has been innovating non-stop to offer solutions across all of its vending-related product range.

Newer articles

- Advantages & Disadvantages of Electric Motors (04/05/2017)

- DC motors advantages and disadvantages over AC motors? (01/08/2017)

- Advantages And Disadvantages Of Single Phase Motors (04/05/2017)

- Tips for Keeping gearheads cool (05/05/2017)

- OTHER POWER ELECTRONIC DRIVERS (04/05/2017)

- ADVANTAGES AND DISADVANTAGES (04/05/2017)

- The different types of gears (09/11/2017)

- Advantages and disadvantages of different types of gears (01/09/2018)

- Electric Motor Advantages and Disadvantages (04/05/2017)

- What are Brushless DC Motors (31/05/2019)

Older articles

- Gearbox Motors vs Integrated Gearmotors (16/04/2008)

- AC or DC? brushed DC or brushless DC Gear Motor? (24/04/2008)

- Dolin seeks help in identifying poor “reliability” in electric motors (01/02/2007)

- WHAT TO CONSIDER WHEN SELECTING A GEAR REDUCER OR GEAR MOTOR (22/11/2012)

- Applying Gear Ratios to DC Motor Systems (08/11/2013)

- What Does Gear Reduction (Gearbox) actually mean for DC gearbox motors? (22/11/2012)

- 4 Common Worm Gear Applications (11/11/2010)

- What is a Reduction Gear? (09/10/2009)

- Light-Load hair foil its high quality (02/09/2009)

- Have a gear motor special designed (04/09/2011)

Join